Item |

Manufacturer |

Part No. |

Supplier |

Supplier's Part No |

QTY |

PCB |

Homemade |

Homemade |

Homemade |

1 |

|

SMA Socket |

Various |

FEC |

105 - 6376 |

2 | |

M2.5 x 6 mm |

Various |

FEC |

142 - 0030 |

26 |

|

M2.5 washer |

Various |

FEC |

161 - 4000 |

18 |

|

M3 x 6 mm |

Various |

FEC |

142 - 0032 |

2 |

|

M3 Washer |

Various |

FEC |

161 - 4001 |

2 |

|

Lid |

Homemade |

1 |

|||

Case |

Homemade |

1 |

|||

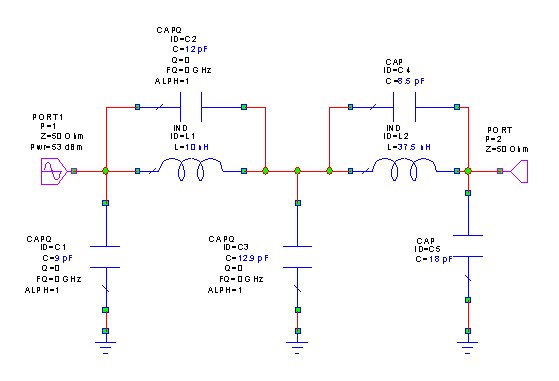

Capacitor |

ATC |

ATC100A1R2BT150X |

RS |

611 - 4335 |

1 |

Capacitor |

ATC |

ATC100A3R9BT150X |

RS |

611 - 4666 |

1 |

Capacitor |

ATC |

ATC100B4R7BT150X |

RS |

611 - 4868 |

1 |

Capacitor |

ATC |

ATC100B6R8BT150X |

RS |

611 - 4688 |

1 |

Capacitor |

ATC |

ATC100B8R2BT150X |

RS |

611 - 4964 |

2 |

Inductor |

Homemade |

1 |

|||

Supplier codes |

RS is RS Components |

FEC is Farnell Electronic Components |

|||

This page last updated 25th Oct 2009